According to the present invention the heat resistant alumina fiber mat may be produced by sintering the precursor of staple alumina fibers at a temperature preferably in the range from 1000 to 1400 c.

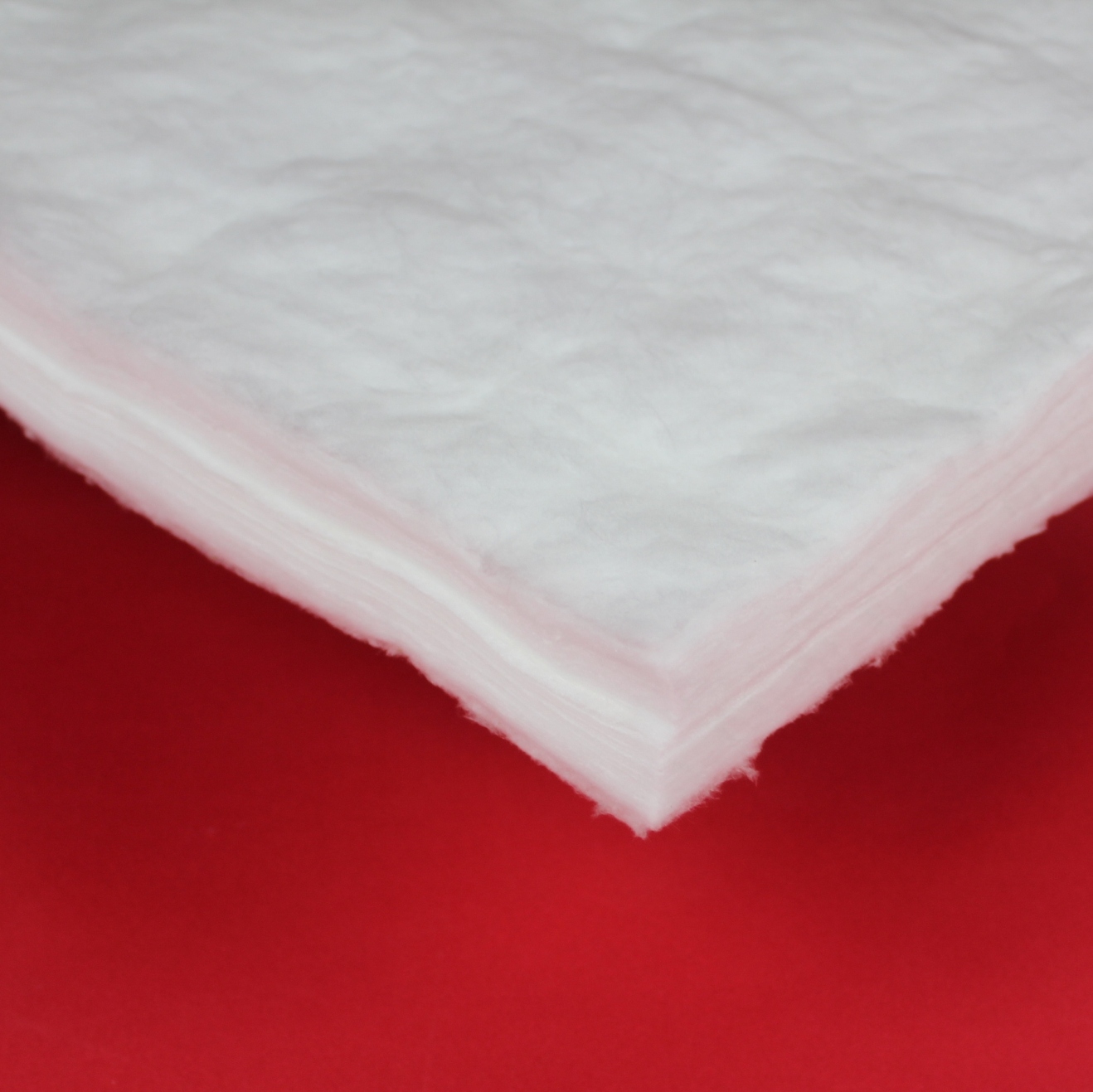

Alumina fiber mat.

Saffil alumina fibers are high purity polycrystalline fibers designed for use in applications up to 1600 c 2912 f.

Alumina mat a layered low density flexible mat made of 100 polycrystalline alumina fiber non rcf designed for use to temperatures as high as 1650 c 3002 f.

Maftec is manufactured on precisely controlled state of the facilities to provide customers with highly consistent properties.

Mainly used as a filling for blankets and gaps.

Saffil alumina mats made of organic and inorganic binders in order to maintain stability in temperature purity and chemical resistance.

Maftec blanket is available in a range of densities and sizes for a wide variety of thermal applications up to 1 600.

Alumina mat zrci type rsmat 3000 is a high purity high temperature flexible form composed of continuous 97 alumina ceramic fibers designed for use to 1650 c 3002 f.

Polycrystalline alumina fiber maftec.

Shot free low density mat used as fill between rigid insulation materials as well as a.

A heat resistant alumina fiber mat of the present invention is comprised of an accumulated mass of alumina staple fibers and continuous alumina fibers.

Alumina mat s high purity aluminum oxide fibers exhibit lightweight low thermal conductivity low thermal mass and immunity to thermal shock.

Since their development in the early 1970s saffil fibers have been used successfully to solve problems in demanding high temperature insulation and many other specialty applications.

The alumina fibers employed in the present.

This prevents embrittlement that usually occurs after extended use at elevated temperatures.

To produce staple alumina fibers collecting these staple fibers together to form an accumulated mass in the form of a mat and sewing the accumulated mass with continuous alumina filaments obtained by sintering the precursor of continuous alumina filaments at a temperature preferably in.

A minor addition of silica modifies the fiber s microcrystalline structure which inhibits unwanted grain growth.

Alumina fiber mat with our itm fibermax we can provide you with an ideal component for thermal insulation of electric heated laboratory and industrial furnaces with an application temperature up to 1 600 c.